BDV test means Breakdown Voltage Test. It is done for checking the dielectric strength of the oil of the Transformer. Dielectric strength means the maximum capacity to withstand voltage of insulating oil. This test shows the dielectric strength of Transformer oil.

For the purpose of BDV test, oil sample from Transformer is taken in a Sample Bottle. While taking sample of oil from transformer, Sample bottle should be flushed well by Transformer oil and oil in Sample bottle should be vented properly so that atmospheric moisture could not ingress in the sample oil. A typical way of taking oil sample in Sample Bottle is shown in figure below.

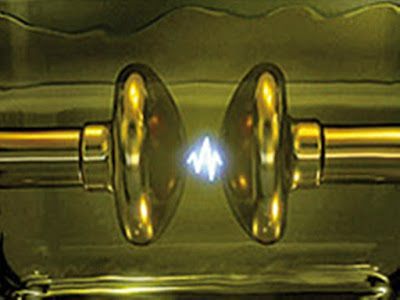

Now slowly rising voltage is applied between the electrodes. Rate of rise of voltage is generally controlled at 2 KV/s and observe the voltage at which sparking starts between the electrodes. That means at which voltage dielectric strength of transformer oil between the electrodes has been broken down. A typical value of BDV Test result for 220 / 6.6 kV Transformer oil is 65 kV and moisture content should be less than 10 ppm.

Thank you!

Which iec rule says that for 220/6.6 KV the BDV to be 65KV and oil ppm to be less than 10pp.

The values are typical. Refer relevant IEC for guideline.

What is standard value of BDV test of Xmer Oil.