We have already discussed about staring methods of Single Phase Induction Motor. If you miss that please read here,

1) Revolving Field Theory of Single Phase Induction Motors

2) Starting Methods of Single Phase Induction Motors

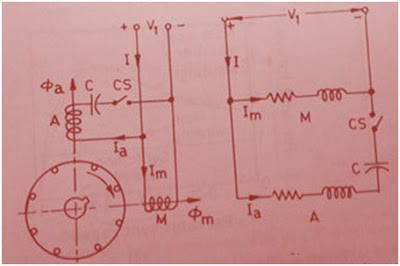

The schematic diagram of Capacitor Split Phase Motor is shown in figure below.

Like in resistor split phase motor, there are two windings, Main and Auxiliary winding but the basic difference between the two method is that in Capacitor Split Phase Motors a capacitor of suitable value is connected in series with the auxiliary winding. Capacitor is connected in series with the auxiliary winding to obtain the desired time phase displacement between the auxiliary winding current Ia and main winding current Im. A centrifugal Switch is also provided the cut out auxiliary winding when the speed of Single Phase Induction Motor reaches 70 to 80% of synchronous speed.

You may like to read,

Purpose of Centrifugal Switch in Induction Motor

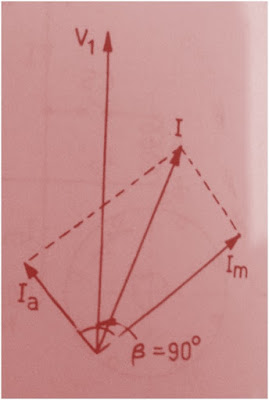

As can be seen from the phasor diagram of Capacitor Split Phase Motor, there is an angle of β between the auxiliary winding current Ia and main winding current Im.

Mind that the angle between the auxiliary winding current Ia and main winding current Im is 180° if there is main winding alone and because of this Single Phase Induction Motor cannot start by itself.

Also, the torque produced in any machine is directly proportional to IaImSinβ, therefore in this method of starting, there will be a net starting torque and the motor will start. The value of Capacitor used shall be selected based on the load starting torque requirement. If the starting torque requirement of load is more, then angle β shall be made more by selecting higher value of Capacitor. A maximum starting torque can be obtained by this method of starting if angle β = 90°. But to have β = 90°, the size and cost of Capacitor will increase. Therefore a compromise is made in between the load starting torque requirement and size & cost of Capacitor.

It shall be noted that, auxiliary winding and Capacitor are in circuit for a short time only, and therefore these can be designed for a minimum cost. The torque speed curve for Capacitor Split Phase Motor is depicted in figure below.

It is clear from the figure that starting torque in this method is high. Capacitor Split Phase Motors have a typical power rating of 100 to 800 Watts. The value of starting Capacitor varies from 20 to 30 microF for 100 Watt Motors and 60 to 100 microF for 750 watt Motors. AC electrolytic capacitors are mostly used in this method of starting but Motors shall not be frequently started else electrolytic capacitors may get overheated and damage.