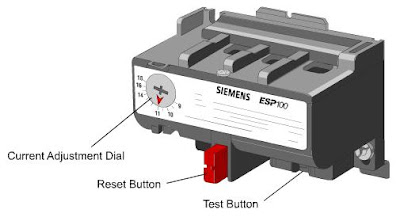

Thermal Overload is widely used for Motor Protection. Basically Thermal Overload Relay is an overcurrent protection of the simplest type. The working principle of Thermal Overload Relay is quite simple but interesting. Figure below shows a typical Thermal Overload Relay. An adjustment dial located on the unit allows the ampere trip setting.A manual test button is provided to test the operation of the overload relay control contacts.

It can be seen from the above figure that metal having greater coefficient of thermal expansion has more expansion when heated. Now we want to use this feature in the protection of a Motor.

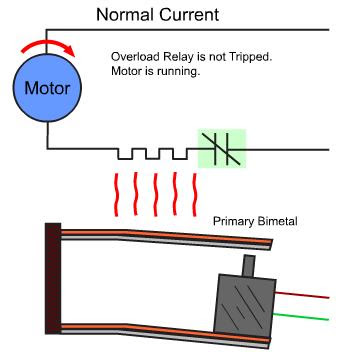

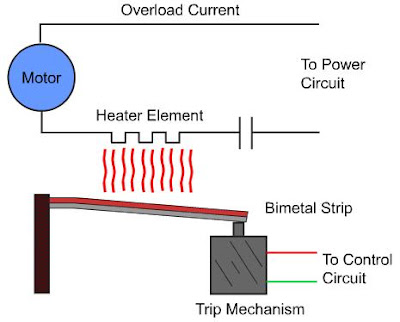

A bimetallic overload relay consists of a small heater element wired in series with the motor and a bimetal strip that can be used as a trip lever. The bimetal strip is made of two dissimilar metals bonded together. The two metals have different thermal expansion characteristics, so the bimetal strip bends at a given rate when heated. Under normal operating conditions, the heat generated by the heater element will be insufficient to cause the bimetal strip to bend enough to trip the overload relay.

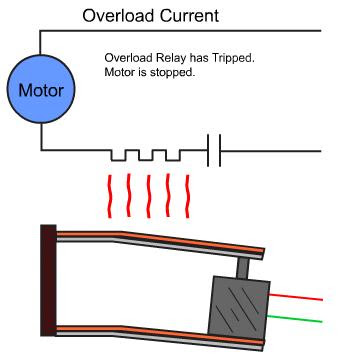

As current rises, heat also rises. The hotter the bimetal strip becomes, the more it bends. In an overload condition, the heat generated from the heater will cause the bimetal strip to bend until the mechanism is tripped, stopping the motor. Some overload relays equipped with a bimetal strip are designed to reset the circuit automatically when the bimetal strip has cooled and reshaped itself, restarting the motor. If the cause of the overload still exists, the relay will trip again and reset at given intervals. Care must be exercised in the selection of this type of overload relay, since repeated cycling will eventually damage the motor.

It should be noted that the bimetallic strip of Overload Relay will not instantly heat up to bend rather will take some finite time to heat up and bend and therefore Thermal Overload Relay is proffered where overcurrent for some short duration is permitted.

If overload or over current falls down to normal value before this predetermined time, the relay will not be operated to trip the protected equipment. A typical application of thermal relay is overload protection of electric motor.

In certain applications, the motor may be installed in a location having a constant ambient temperature. However, the motor control and overload relay may be installed in a location with a varying ambient temperature. In such cases, the trip point of the overload relay will vary with the temperature of the surrounding air as well as current flowing through the motor, which can lead to premature and nuisance tripping. Ambient Compensated Bimetal Overload Relays are designed to overcome this problem. A compensated bimetal strip is used along with a primary bimetal strip. As the ambient temperature changes, both bimetal strips will bend equally and the overload relay will not trip the motor as shown in figure below. However, current flow through the motor and the heater element will affect only the primary bimetal strip. In the event of an overload condition, the primary bimetal strip will engage the trip unit.

|

| Normal Operation |

|

| Overload Condition |

Overload relays typically operate on an inverse time curve where the tripping time becomes less as the current increases. They are rated by trip class. Trip class specifies the length of time it will take for the relay to open in an overload condition. Classes 5, 10, 20 & 30 are the most common. Class 5, 10, 20 & 30 overload relays will trip within 5, 10, 20 & 30 seconds respectively at 600% of motor full load amps. Class 5 is usually used for motors requiring extremely fast tripping.

Sorry for my English, I'm Indonesian.

Is it possible that Thermal Overload Relay not tripped above the set point after determined time achieve?

Like: Set 50A, Class 10. The current condition is already above 50A – let say 60A, for more than 20 seconds, and the Relay still not tripped.

What part of the Thermal Overload Relay is broken?

Thanks for your attention/

Warm regards,

Herbrata