A universal motor is a special type of motor which is designed to run either on DC or single phase AC supply. Universal Motors are so named because they can run both on AC as well as DC. A universal motor has a high starting torque and variable speed characteristics. Such motor runs at dangerously high speeds during no load.

The universal motor is basically a series DC motor which is specially designed to operate on AC as well as on DC. A standard DC series motor has very poor characteristics when operated on AC, mainly due to two reasons:

- The high reactance of both the armature and field windings limits AC current to a much lower value than DC current for the same line voltage.

- If solid steel is used for the stator frame, AC flux will produce large eddy currents in the frame with consequent heating.

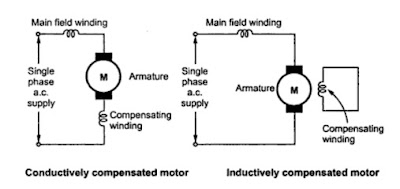

To insure satisfactory operation of the universal motor from an AC power source, some modifications are necessary. The reactance of the series field and armature windings must be reduced as much as practicable. The reactance of the series field winding can be somewhat reduced by using fewer turns of heavier wire. However, it would not be practical to eliminate the reactance voltage drop due to the series field since that would also eliminate the magnetic field. The reactance voltage drop due to the armature winding can be practically eliminated by use of a compensating winding. The compensating winding is connected in series with the armature winding (conductive compensation) and arranged such that the ampere-turns of the compensating winding oppose and neutralize the ampere-turns of the armature. To realize this compensation, the compensating winding is displaced by 90 electrical degrees from the field winding.

The reactance of the armature winding can be lowered by placing a compensating winding on the stator so that the fluxes oppose or “cancel” each other. This same compensating winding can be connected in series with the armature winding. In this case, the motor is said to be conductively compensated. Under these conditions, the universal motor will have similar operating characteristics whether on AC or DC power.

The compensating winding may be simply shorted upon itself, so that it behaves like a short circuited secondary of a transformer (the armature winding acting as the primary). The induced AC current in the compensating winding again opposes the armature current and the motor is said to be inductively compensated. The reactance of the field winding can be kept low by limiting the number of turns.

Types of Universal Motor:

There are two types of Universal Motor:

- Non-compensated Type with Concentrated Poles

- Compensated Type with Distributed Field.

Construction of Universal Motor:

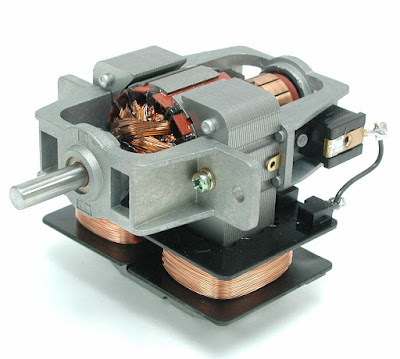

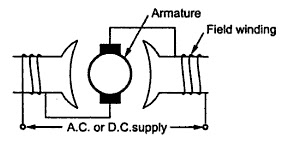

Construction of a universal motor is very similar to the construction of a DC machine. It consists of a stator on which field poles are mounted. Field coils are wound on the field poles.

Non-Compensated Universal Motor:

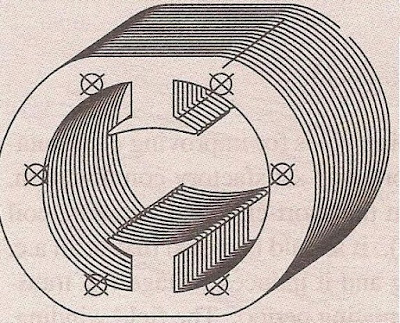

The Non-compensated motor has two salient poles and it is laminated as shown in figure below.

The armature is of wound type and the laminated core is either straight or skewed slots. The leads of the armature winding are connected to the commutator. High resistance brushes are used along with this type of motor to help better commutation. An equivalent Non-compensated type Universal Motor is shown in figure below.

Compensated Type with Distributed Field:

The compensated type Universal Motor consists of distributed field winding and the stator core is similar to that of split-phase motor. We know that split phase motors consist of an auxiliary winding in addition to main winding. Similar to the split phase motors, the compensated type also consists of an additional winding. The compensating winding helps in reducing the reactance voltage which is caused due to alternating flux, when the motor runs with the AC supply.

An equivalent Compensated type Universal Motor is shown in figure below.

Working Principle of Universal Motor:

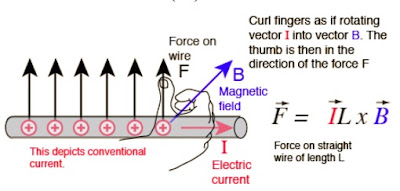

A universal motor works on either DC or single phase AC supply. When the universal motor is fed with a DC supply, it works as a DC series motor. When current flows in the field winding, it produces a magnetic field. The same current also flows from the armature conductors. When a current carrying conductor is placed in an electromagnetic field, it experiences a mechanical force. Due to this mechanical force, or torque, the rotor starts to rotate. The direction of this force is given by Fleming’s left hand rule.

Force on conductor, F=I(LxB)

where I is the current flowing through the windings and L is active length of conductor.

Now the question is, how does a DC motor work on AC supply?

From the above image, the direction of the Resultant Force due to Current in the winding in presence of Magnetic field can be calculated. This Force called Lorentz Forece, is in the direction along which the Armature Coil rotates and hence the shaft.

If the supply is DC, the polarity never reverses. So we get the field and the current in the same direction always and hence a net force in a particular direction on the conductors due to which the rotor rotates.

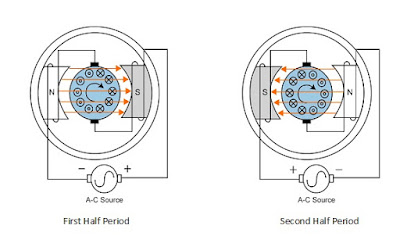

If the supply is AC, the polarity changes between +ve and –ve, 50 times per second. So, the direction of current as well as the Magnetic Field changes and hence we get the Resultant Force in different directions.

As in a DC Series motor, since the field is connected in series with the Armature, both the Current and Field Direction changes simultaneously and as a result, the Resultant Force always remains in the same direction, as can be seen from the direction ( take the direction of I as the opposite to the original and B as the opposite to the original and using Fleming’s left hand rule.) Thus, even if the polarity is changed, the motor continues to run in the same direction. The poles are laminated because they invariably run on AC and Eddy Currents are induced in it. Thus laminated poles reduces the Eddy Current.

Application of Universal Motor:

- Universal motors find their use in various home appliances like vacuum cleaners, drink and food mixers, domestic sewing machine etc.

- The higher rating universal motors are used in portable drills, blenders etc.

Thank you!

Hello sir!

Similar to DC series motor, if we use AC current in DC shunt motor then also direction of current in both armature and field winding will change simultaneously then why can't we use it as universal motor? Please clarify my doubt, I'm badly confused.

Field winding of dc shunt motor have large inductance compare to armature winding which causes a large lag between the field and armature current which results into a very poor torque generation and not useful for practical applications.

Thanks for this answer

Hllo, i have 200 watt dc motor of 230v supply of hand blender, but the circuit of that blender is dead, so i want to run it, tell me how can i run it by ac supply without using transformer.

Thanks for the article, good information.

Thank you for the interesting and informative article. I was just wondering, in the first image the stator windings are in a different location (offset) to many other universal motors. Please could you explain why this is, how it works and what the benefits of this are.