The winding is the component with the highest temperature within the transformer and it is the component which is subjected to the fastest temperature increases as the load increases. Therefore for the control of the temperature parameter within the transformer, the temperature of the winding, as well as top oil, is measured. The temperature of winding of Transformer is measured using Winding Temperature Indicator (WTI) and the temperature of Transformer Oil is measured using Oil Temperature Indicator.

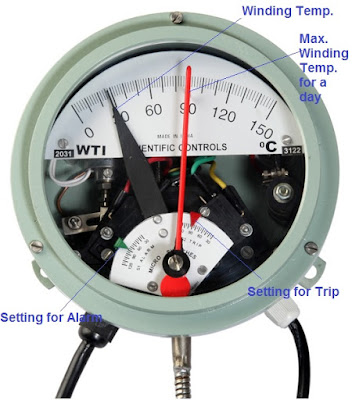

As can be seen from the above figure, Black needle shows the current winding temperature while the Red needle shows the highest winding temperature reached for a particular day. This Red needle needs to be reset manually.

Also, for setting winding temperature for Alarm and Trip, two knobs are provided. The Green knob shows the setting of winding temperature for Alarm and Red knob shows the Trip temperature setting as shown in figure.

Construction Detail of Winding Temperature Indicator, WTI:

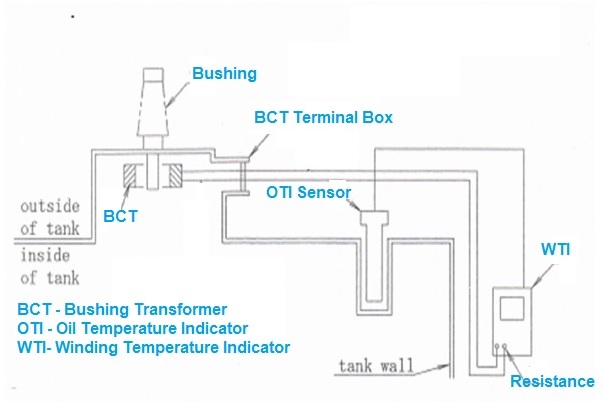

Winding temperature indicator consists of a sensor bulb placed in an oil filled pocket in the transformer tank cover. The bulb is connected to the Instrument housing by means of two flexible capillary tubes. One capillary is connected to the measuring bellow of the instrument and the other to a compensating below.

Working Principle Winding Temperature Indicator:

An indirect system is used to measure winding temperature, since it is dangerous to place a sensor close to the winding due to the high voltage. The indirect measurement is done by means of a Thermal Image.

The measuring system is filled with a liquid which changes its volume with rising of temperature. Inside the instrument is fitted a heating resistance which is fed by a current proportionate to the current flowing through the transformer winding. To do this we connect the terminal of the heating resistance with the Bushing Current Transformer so that reflection of change in load is reflected in the Winding Temperature Indicator, WTI.

The Winding Temperature Indicator, WTI is provided with a maximum temperature indicator. The heating resistance is fed by a current transformer associated to the loaded winding of the transformer. The increase in the temperature of the resistance is proportionate to that of the winding. The sensor bulb of the instrument is located in the hottest oil of the transformer, therefore, the winding temperature indicates a temperature of hottest oil plus the winding temperature rise above hot oil Level the hot spot temperature.

Winding Temperature of Transformer may rise due to increased loading of Transformer or due to some internal fault. Normally the Winding Temperature Indicator, WTI gives alarm at 85 °C and Trip signal at 95 °C in India.

The oil temperature is measured as normal with a bulb in a pocket. The measuring system also has a mainly designed heating element, to measure the transformer load. This heating element is a thermal model of the winding. The heating element is connected to the contemporary transformer (CT) through a matching Resistance or a matching Unit, to allow putting the best winding temperature gradient.Get more information Click hear

simply expalain what is temperature gradient of transformer

What can I do when 10 mva power transformer increase winding temperature over 90 degree when load of power transformer is 330 amp.

Is there any forced cooling logic for the transformer? What is its setting?

HOW TEMPERATURE OF WINDING IS MEASURED IN OIL TYPE TRANSFORMER

Using thermal image method which is described in the post.

Why wti setting is more than oti settin??

The source of heat is ohmic loss in winding. Therefore, the temperature of winding is supposed to be more than the oil. Hence, WTI setting is more than OTI.

can you used a thermocouple to measure the winding temp instead of thermal image? What is the latest technology for this?

how do i mechanically set the gauge for trip and for alarm

There is a lever for the purpose.

I would like to know the standard specifications of OTI sensor ( How many Diemensions for Bulb & Capillary). Please.

can you explain why winding temp is being indicated by two bellows…that is measuring bellow and compensating bellow…with WTI CT only we can measure the the temperature right…what is the need of sensor bulb above the tank cover..can you pls elaborate

Plz reply fast sir. different capacity transformer of different locations at our power generation station but all transformers in wti operated different different timings, what is the reasons

First of all you should investigate the reason of actuation of wti as it operated for all your transformer. This means some common cause.

Then only you can investigate the reason for actuation of wti at different times.

I have a problem with WTI, the winding temperature is high compared to normal oil temperature and normal transformer current, is there a resistance setting calculation to calibrate

Winding tamprechar jyada hoga oil tamprechar se jyada hoga

For example = agar water heater ko thanda karne ke liye pani ka use karte hai to pani ka tamprechar kabhi bhi heater se jyada nahi hoga