Vacuum Circuit Breaker

Vacuum Circuit Breaker (VCB) is one where vacuum of the order of 10-6 to 10-10 torr is used as an arc quenching medium. 1 torr is equivalent to a pressure represented by a barometric head of 1 mm mercury. Vacuum Circuit Breaker is used for low and medium voltage applications.

Construction of Vacuum Circuit Breaker

Vacuum Circuit Breaker consists of Enclosure, Contacts, Vapor Condensing Shield, Metallic Bellows and Seal.

Enclosure. The enclosure is made of impermeable insulating material like glass. The enclosure must not be porous and should retain high vacuum of the order of 10-7 torr.

Contacts. There are two types of contacts, moving and fixed. The moving contact is connected with large stem connected to operating mechanism of breaker. Contacts of Vacuum Circuit Breaker have generally disc shaped faces. The disc is provided with symmetrical grooves in such a way that the segments of the two contacts are not in the same line. The magnetic field set-up by the components of currents with such geometry causes the plasma of the arc to move rapidly over the contacts instead of remaining stable at one point. The concentration of the arc is thus prevented and the arc remains in diffused state. The sintered material used for contact tip are generally copper-chromium or copper bismuth alloy.

Vapor Condensing Shield. These metallic shields are supported on insulating housing such that they cover the contact region. The metal vapor released from the contact surface during arcing is condensed on these shields and is prevented from condensing on the insulting enclosure.

Metallic Bellows. One end of the bellows is welded to the enclosure. The other end is welded to the moving contact. The bellows permit the sealed construction of the interrupter and yet permit movement of the contact. Stainless steel bellows are generally used in vacuum interrupters. Carefully observe every component of Vacuum Circuit Breaker as shown in figure below.

Arc Extinction in Vacuum Circuit Breaker (VCB)

The arc interruption process in Vacuum Circuit Breaker interrupter is quite different from that in other types of circuit breakers. The vacuum as such is a dielectric medium and arc cannot persist in ideal vacuum. However, the separation of current carrying contacts causes the vapor to be released from the contacts. Thus, as the contacts separate, the contact space is filled with vapor of positive ions liberated from the contact material.

The vapor density depends on the current in the arc. During the decreasing mode of the current wave the rate of release of the vapor reduces and after the current zero, the medium regains the dielectric strength provided vapor density around contacts has substantially reduced.

While interrupting a current of the order of a few hundred amperes by separating flat contacts under high vacuum, the arc generally has several parallel paths. Thus the total current is divided in several parallel arcs. The parallel arcs repel each other so that the arc tends to spread over the contact surface. Such an arc is called diffused arc. The diffused arc can get interrupted easily.

At higher values of currents of the order of a few thousand amperes, the arc gets concentrated on a small region and becomes self-sustained arc. The concentrated arc around a small area causes rapid vaporization of the contact surface.

The transition from diffused arc to the concentrated arc depends upon the material and shape of contact, the magnitude of current and the condition of electrodes. The interruption of arc is possible when the vapor density varies in phase with the current and the arc remains in the diffused state. The arc does not strike again if the metal vapor is quickly removed from the contact zone.

Thus the arc extinction process in vacuum circuit breaker is related to a great extent to the material and shape of the contacts and the technique adopted in condensing the metal vapor. The contact geometry is so designed that the root of the arc keeps on moving so that the temperature at one point on the contact does not reach a very high value.

The rapid building up of dielectric strength after final arc extinction is a unique advantage of vacuum circuit breaker. They are ideally suitable for capacitor switching as they can give restrike free performance.

Degree of Vacuum in VCB Interrupters

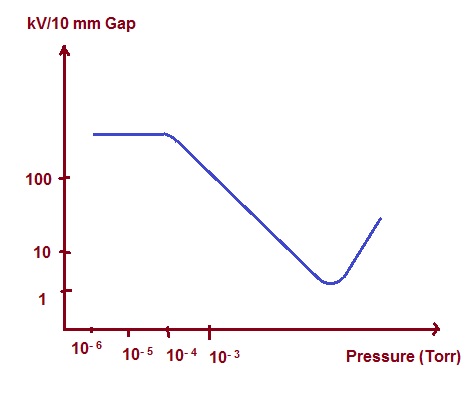

The breakdown voltage of contact gap varies with the absolute pressure in the vacuum circuit breaker interrupter unit. As the absolute pressure is reduced from 10-1 Torr to 10-3 Torr, the dielectric strength (kV/mm) increases but above 10-4 Torr, the breakdown strength and pressure characteristic becomes almost flat as shown in figure below.

The dielectric strength in this region is above 12 kV /mm. In vacuum interrupters vacuum level of the order of 10-6 to 10-10 Torr is used. This is called high vacuum range. During the passage of time and after arc interruptions, the vacuum level goes on reducing. However it remains in the range of 10– 5 Torr and 10-8 Torr. Vacuum in the range of 10-3 is sufficient for interruption.