DC Machines can be tested by three different methods namely Direct Method, Indirect Method and Regenerative Method. Direct Method of testing of DC Machine, also known as Brake Test (if carried out for a DC Motor) will be discussed in this post.

Direct method is suitable for small DC machines. In Direct Method, the DC machine is subjected to rated load and the entire output power is wasted. The ratio of output power to the input power gives the Efficiency of DC Machine. For a DC Generator the output power is wasted in resistor.

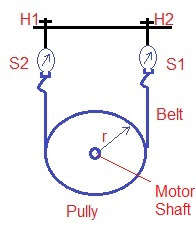

Direct Method of testing when conducted on a motor is also known as Brake Test. Brake Test of DC Motor is carried out as shown in figure below.

A belt around the air cooled pulley has its end attached to the spring balance S1 and S2. Using belt tightening hand wheels H1 and H2, the load of motor is adjusted to its rated value. Assuming the spring balance to be calibrated in kilogram, then rated load on the DC motor is given as

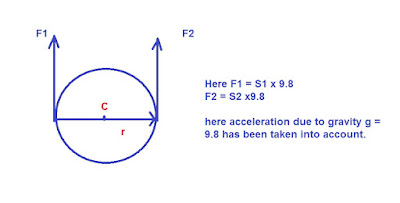

Motor Output Power = Torque x Angular Speed

= (Force x Radius) x Angular Speed

As the torque because of force F1 and F2 are opposing each other, therefore net torque will be subtraction of torque because of F1 and F2.

Therefore,

Motor Output = ω (S1 – S2) x r x9.8 Watt

Now assuming the terminal voltage of DC Motor to be Vt and IL to be the load current then,

Power input to the DC Motor = VtIL

Thus the efficiency of DC Motor can be calculated as below.

Efficiency = Output / Input

= [ω (S1 – S2) x r x9.8 Watt] / VtIL

For conducting Brake Test on DC Series Motor, it must be ensured that belt is sufficiently tight before the motor is switched on to the sully as DC Series Motor shall not be started at no load.

1) The Spring Balance Readings are not stable rather it fluctuates.

2) Output power is wasted.

3) The frictional torque at a particular setting of Hand wheel H1 and H2 do not remain constant.

Thanks

Any thing with disadvantages ussualy it can’t miss its advantages ,,,,,,it’s just request if possible let’s them also be specified in this document….thank you

Good