Cogging phenomenon is observed in Squirrel Cage Induction Motor during starting for certain combination of Stator and Rotor Slots. In Cogging motor fails to start at all. For better understanding a view of Stator Core Laminations, Stator Core and Rotor of Squirrel Cage Induction Motor is shown in figure below.

Squirrel Cage Induction Motor Stator Core Lamination:

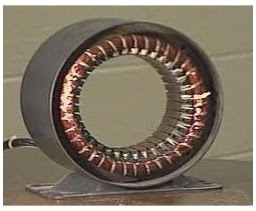

Squirrel Cage Induction Motor Stator Core:

Squirrel Cage Induction Motor Rotor:

Condition for Cogging:

If the number of Stator Slots are either equal to or integral multiple of Rotor Slots then Cogging will definitely be observed. So this is the criteria for Cogging in Squirrel Cage Induction Motor.

Why Cogging Observe?

Let the number Stator Slots = S1 and that of Rotor Slots = S2

If the number of Stator Slots S1 is either equal to or integral multiple of Rotor Slots S2, then the variation of Reluctance as a function of space will have pronounced effect producing strong forces than the accelerating torque and because of this Squirrel Cage Induction Motor will fail to start.

In other words, If the number of Stator Slots S1 is either equal to or integral multiple of Rotor Slots S2, then the Reluctance is very low as teeth of Stator and Rotor face each other and therefore the Rotor will not try to go in high Reluctance region i.e. magnetic locking will take place and therefore Rotor will not rotate. When the rotor teeth and stator teeth face each other, the reluctance of the magnetic path is minimum that is why the rotor tends to remain fixed.

How to Prevent Cogging?

- In order to avoid such Cogging a proper number of rotor slots are to be selected in relation to number of stator slots.

- In addition rotor slots will be skewed by one slot pitch to minimize the tendency of Cogging and noisy operation while running.

- Effect of skewing will slightly increase the rotor resistance and increases the starting torque. However this will increase the leakage reactance and hence reduces the starting current and power factor.

Selection of Number of Rotor Slots:

The number of rotor slots may be selected using the following guidelines.

To avoid Cogging and Crawling:

- S1 ≠S2

- S1 – S2 ≠ ±3P

To avoid noisy operation S1– S2 ≠ ±1, ±2, (±P ±1), (±P ±2)

Why Cogging and Crawling Not Observed in Slip Ring Induction Motor?

Cogging and Crawling is not predominant in Slip Ring Induction Motor as these Motors are started with higher starting torque with external resistance in Rotor circuit.

Thank you! Please leave your feedback in comment box for improvement.

Thank you so much for explanation.

very good explanation

Thank you!

Thanks