Doubly-fed Induction Generators in industry are used to generate electrical power in large wind turbines. This is primarily due to the many advantages of Doubly-fed Induction Generators than other types of generators in applications where the mechanical power provided by the prime mover driving the generator varies greatly e.g. wind blowing at variable speed on the bladed rotor of a wind turbine.

Large-size wind turbines are basically divided into two types which determine the behavior of the wind turbine during wind speed variations:

- Fixed-Speed Wind Turbines

- Variable-Speed Wind Turbines

In Fixed-Speed Wind Turbines, three phase synchronous generators are generally used. Because the generator output is tied directly to the grid (local ac power network), the rotation speed of the generator is fixed and so is the rotation speed of the wind turbine rotor. Any fluctuation in wind speed naturally causes the mechanical power at the wind turbine rotor to vary and, because the rotation speed is fixed, this causes the torque at the wind turbine rotor to vary accordingly. Whenever a wind gust occurs, the torque at the wind turbine rotor increases significantly while the rotor speed varies little. Therefore, every wind gust stresses the mechanical components mainly the gear box in the Wind Turbine and causes a sudden increase in rotor torque, as well as in the power at the wind turbine generator output. Any fluctuation in the output power of a wind turbine generator is a source of instability in the power network to which it is connected.

In Variable-Speed Wind Turbines, the rotation speed of the wind turbine rotor is allowed to vary as the wind speed varies. This precludes the use of asynchronous generatorsin such Wind Turbines as the rotation speed of the generator is not constant when its output is connected directly to the grid.

This is where Doubly-fed Induction Generators come into play, as they allow the generator output voltage and frequency to be maintained at constant values, no matter the generator rotor speed and thus, no matter the wind speed.

This is achieved by feeding AC currents of variable frequency and amplitude into the generator rotor windings. By adjusting the amplitude and frequency of the ac currents fed into the generator rotor windings, it is possible to keep the amplitude and frequency of the voltages at stator produced by the generator constant, despite variations in the wind turbine rotor speed and, consequently, in the generator rotation speed caused by fluctuations in wind speed. This also allows operation without sudden torque variations at the wind turbine rotor, thereby decreasing the stress imposed on the mechanical components of the wind turbine and smoothing variations in the amount of electrical power produced by the generator. Using the same means, it is also possible to adjust the amount of reactive power exchanged between the generator and the AC power network. This allows the power factor of the system to be controlled e.g. in order to maintain the power factor at unity.

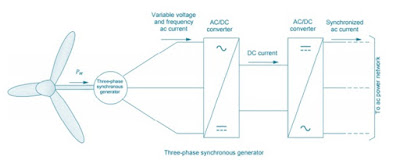

While using a Doubly-fed Induction Generator in variable-speed wind turbines allows electrical power generation at lower wind speeds than with fixed-speed wind turbines using an asynchronous generator. It would be possible to obtain similar results in variable-speed wind turbines using a three-phase synchronous generator and power electronics, as shown in figure below.

In this setup, the generator rotates at a speed that is proportional to the wind speed. The AC currents produced by the generator are converted into dc current by an AC/DC converter, and then converted by another AC/DC converter back to AC currents that are synchronous with the AC power network. It is therefore necessary for the power electronics devices used in such a circuit to have the size and capacity to process 100% of the generator output power.

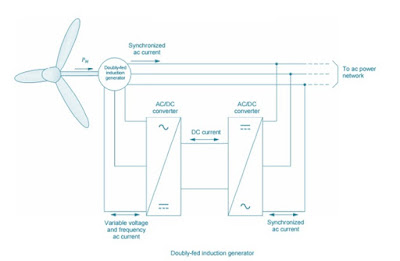

The power electronics devices used in Doubly-fed Induction Generators need only to process a fraction of the generator output power i.e. the power that is supplied to or from the generator rotor windings which is typically about 30% of the generator rated power. Consequently, the power electronics devices in variable-speed wind turbines using doubly-fed induction generators typically need only to be about 30% of the size of the power electronics devices used for comparatively sized three-phase synchronous generators, as shown in figure below.

This reduces the cost of the power electronics devices, as well as the power losses in these devices and hence more efficiency.

In the 4th para starting you have written "This is achieved by feeding AC currentsof variable frequency and amplitude into the generator rotor windings." It is not clear what you mean . First the rotor of the Generator is fixed with prime mover for it's rotation and it has field windings with magnetic lines of forces to generate power at the stator windings . Will you tell us what you have said that can be done .

In case of wind turbine the speed of prime mover is not constant rather it changes. Therefore as the speed of prime mover is changing,hence to have constant output voltage and frequency at stator terminals, we supply variable AC to the rotor using power electronics.

OK, How small can all of that be made with a 10 year life? and how much will it cost in production.