HRC stands for High Rupturing Capacity. HRC Fuse has high rupturing capacity. Because of its high current rupturing capacity, a special method for extinguishing arc is required in the design of HRC Fuse.

Construction of HRC Fuse:

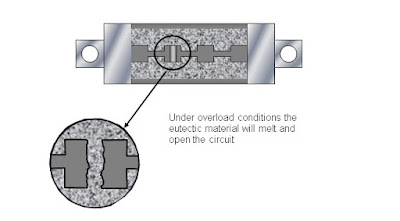

HRC Fuse consists of heat resisting ceramic body having metal end caps on which silver current carrying element is welded in a special manner as shown in figure below.

As clear from the figure above, the fuse element have a portion of Tin Alloy, known as a Eutectic Material. This alloy is used to give the fuse specific operating characteristics. Also, constrictions in the fuse element are provided which play a very vital role in the operation of Fuse. The space between the body surrounding the Fuse element is filled filling powder such as with Silica Send, Chalk, plaster of peris etc.

Working Principle of HRC Fuse:

Under normal operating conditions the current flowing through the Fuse element does not provide enough energy to melt the element. The heat produced is absorbed by the surrounding filling powder. If a large current flows the energy produced melts and vaporizes the fuse element before the fault current reaches the peak. The chemical reaction between the fuse element vapour and filling powder results into high resistance material which helps in extinguishing the arc.

Now, will HRC Fuse blow off in case of overload condition?

Under overload condition the fuse element will not blow off but if the condition exists for prolonged period, the Eutectic Material will melt and break the fuse element. This is the purpose of providing Eutectic Material in the HRC Fuse.

Will Eutectic Material blow off during short circuit condition?

Under high current short circuit conditions the smaller area constricted parts of the fuse element will melt rapidly and vaporize and will break before the Eutectic Material. That is why constrictions are provided in the HRC Fuse element.

Characteristics of HRC Fuse:

A Fuse operates when its element melts due to heat produced by I2RF, where RFis Fuse resistance. This heat produced increases if the current flowing through the Fuse element increases. Therefore, we can conclude that a Fuse element will melt faster for large fault current while it will take some time for lower value of fault current. This time-current relationship of Fuse is known as Characteristics of Fuse and is very useful for proper selection of Fuse for a particular circuit and for coordination purpose. A typical Fuse characteristic is shown in figure below.

How to Interpret the Fuse Characteristics?

In the above figure, curve for three Fuses of rating 60 A, 100 A and 200 A are give. We select Fuse of rating 60 A for the sake of understanding. See, if the current flowing through the Fuse element is around 350 A then the Fuse element will melt in .02 sec i.e. 20 ms while if the current is around 225 A then it will take 50 ms to melt. Thus we see that the Fuse characteristic is Inverse Time. Higher the current, lower will be the time to melt.