There are two types of Braking: i) Mechanical Braking and ii) Electrical Braking.

In Mechanical Braking the speed of the machine is reduced solely by mechanical process but Electrical Braking is far more interesting than that because the whole process is depended on the current and torque directions. We can say that it is the process of reducing speed of any rotating machine. The application of braking is seen at almost every possible area, be it inside the motor used in factories, industrial areas or be it in locomotives or vehicles. Everywhere the use of Mechanical and Electrical brakes is inevitable.

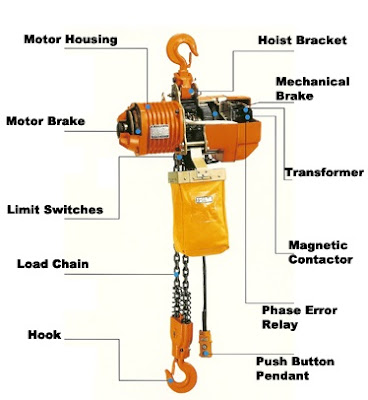

The need for Electrical Braking can be visualized by some examples. Therefore I will explain with some interesting examples. Suppose a loaded hoist is lowered or an unloaded hoist is lifted, in both the cases the net torque will assist the motion.

Therefore steady state operation for both the cases can be obtained by adding a mechanical brake (it is just like when you are driving down a slope by your Bike, you need to apply Break for having a constant speed else the Bike will accelerate). But unfortunately, Mechanical Brakes have a number of disadvantages:

- It needs frequent maintenance and replacement of Brake Shoes

- Lower life of Mechanical Brakes

- Braking power is wasted as heat

This calls for some smart method for Braking. Here Electrical Braking helps. The disadvantages of Mechanical Brakes are overcome by the use Electrical Braking in which Motor is made to operate as a Generator converting mechanical energy into electrical energy and producing torque in a direction to oppose the motion.

But for enhancing the reliability, Mechanical Brakes are also provided along with the Electrical Brakes.

Now coming to next scenario. Suppose we need to decrease the speed of a Motor, so obviously we need to have deceleration of Motor. As we know that deceleration of Motor occurs when the load torque is more than the Motor torque. For applications where Load torque is always present, simply reducing the Motor current will reduce the Motor torque and thus we can have Motor torque less than the Load torque and hence deceleration will take place. But assume an application, where Load torque is not always present, then for Braking we need to have either Electrical Braking or Mechanical Braking.

Stopping is a special case for deceleration where the speed of Motor is brought to zero. In application where we need frequent, quick, smooth or emergency stop we need Electrical Braking as it affects less to the mechanical parts. For example, in suburban Electric Train quick stops are required. Use of Electric Braking allows a smooth stop which doesn’t cause any inconvenience to the passenger and increase the life of Track and wheels and thus saving the cost.

Thank you!