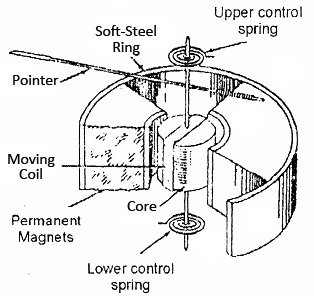

Permanent Magnet Moving Coil or PMMC Instruments are the best for the measurement of DC quantities like voltage and current from accuracy point of view. But there are various factors due to which error in PMMC Instrument reading may develop. To investigate the main sources of errors, let us have a look at the deflection of PMMC instruments which is given as

Ɵ = (G / K)I

where Ɵ = Angular movement of coil

K = Spring constant

G = a constant = NBLd

From the above equation we observe that deflection of PMMC instruments depend on Magnetic Flux density, Spring Constant and current flowing through the moving coil. If any one of the parameter changes with time, that will cause error in PMMC Instruments reading. Thus we can summarize the sources of error as:

Magnetic Flux Density: Magnetic Flux Density decreases with weakening of Permanent Magnet due to ageing and temperature effect which tend to decrease the deflection of needle of instrument.

Spring Constant: The value of Spring Constant decreases with weakening of Spring due to ageing and temperature effect which will increase the deflection for a particular current and magnetic flux density. Note that the weakening of spring have the opposite impact to that of weakening of magnet.

Current: Increase in resistance of moving coil with temperature will decrease the current flowing through the moving coil resulting into error in reading of PMMC Instruments.

Methods to overcome Error in PMMC Instrument:

Well, there are various methods which reduce the probability of error with ageing of PMMC Instruments. We will discuss remedial action for each source of error one by one.

Weakening of Permanent Magnet: To prevent the weakening of Permanent Magnet due to ageing and temperature effect, magnets are aged by heat and vibration treatment during manufacturing process. These processes make the magnet to retain its magnetism over a longer period of time.

Weakening of spring: The weakening of Spring can be reduced by careful use of material and pre-aging during manufacturing process.

In Permanent Magnet Moving Coil or PMMC Instruments, 1°C increase in temperature reduces the strength of spring by 0.04% and reduces the air gap flux density of magnet by 0.02%. Thus the net effect is to increase the deflection of instrument by 0.02% / °C.

Change in Resistance of Moving Coil: Temperature coefficient of resistance of copper is 0.004/°C. When the instrument is used as micro-ammeter or mili-ammeter, the indication of instrument for a constant current will decrease by 0.04% per °C rise in temperature.

Now suppose, the instrument is used as voltmeter. In such case a large resistance made of Manganin is connected in series with the instrument. The temperature coefficient of resistance of Manganin is negligible as compared to copper. As in this case the resistance of copper wire only forms a fraction of total resistance, hence the increase in total resistance with temperature will be negligible. Therefore, no error in PMMC Instrument reading will be introduced with change in temperature.

However the case is different when instrument is used to measure current with Shunt. Mind that Shunts are made of Manganin which have very low temperature coefficient of resistance. In such case the main source of error in PMMC Instrument reading is relatively larger change in resistance of copper moving coil with rise in temperature as compared to rise in temperature of shunt. To reduce the error in PMMC Instrument reading on this account, usually a series resistance is connected with the moving coil. This series resistance is made of the same material as that of shunt i.e. Manganin and called Swamping Resistance.

For detail on how Swamping Resistors eliminate error in PMMC Instruments, please read Why Swamping Resistance in Ammeter?