Electrodynamic type instrument is used for the measurement of AC and DC quantities unlike PMMC instrument which can only be used for the measurement of DC quantity. This type of instrument is known as Elctrodynamometer type instrument.

Construction of Electrodynamic Type Instrument

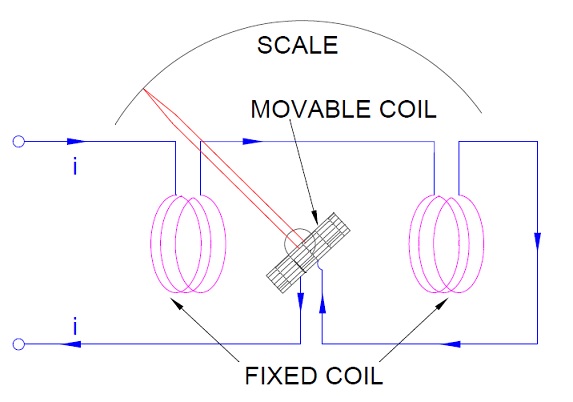

An electrodynamic type instrument consists of Two Fixed Coil, a Moving Coil, Control Spring, Damping Device and Magnetic Shielding arrangement. We will discuss each of them one by one.

Fixed coil is provided for the sake of production of magnetic field. This fixed coil is divided into two sections so that a uniform magnetic field may be achieved at the centre. Further, splitting up fixed coil in two section facilitates passage of instrument’s moving shaft.

Moving coil is serves the purpose of converting the actuating quantity into readable value on the scale. It is generally wound on a non magnetic metallic former. Metallic former shall never be used as it will lead eddy current generation due to changing flux. This eddy current will introduce inaccuracy as eddy current damping is not used in Electrodynamic Instrument.

Air friction damping is employed in electrodynamic type instrument. To provide air friction damping, a pair of aluminium vane is attached to the spindle at the bottom. These vanes move in a sector shaped chamber. Now you might ask, why didn’t we provide eddy current damping by wounding moving coil on metallic former?

Thing is that, the magnetic field produced by the fixed coils are very week because of air cored coil. Therefore an introduction of eddy current damping will distort the main magnetic field and hence will introduce appreciable inaccuracy.

The magnetic filed in electrodynamic type instrument is very week of the order of 0.005 to 0.006 Wb/m2. Therefore it becomes very important to protect the instrument from the effect of external magnetic field. To provide magnetic shielding, normally electrodynamic type instrument is enclosed in a high permeability alloy.

Working Principle of Electrodynamic Type Instrument

For understanding the working principle, first ask yourself what will happen if we connect a PMMC instrument for the measurement of AC quantity? Obviously, your answer will be there will be no deflection in the needle of PMMC instrument. Why?

Since the direction of current is changing in each half cycle, there will be a corresponding change in the direction of magnetic flux. Because of this change of magnetic flux, the torque on moving coil will also change in each half cycle of AC quantity to be measured. Suppose the torque on moving coil for positive half cycle of AC quantity is clockwise then it will change to anticlock wise direction in the negative half cycle. Thus ideally the needle of PMMC instrument shall swing back and forth around zero position. But there is something called inertia, you better know. Due to the inertia of instrument, the needle cannot follow the rapid change in direction of torque at power frequency and therefore merely vibrates around zero position.

Now suppose, if we were able to reverse the direction of magnetic flux each time the direction of AC quantity changes through the moving coil then we can have a unidirectional torque. Thus we can measure the AC quantity. Actually this method of reversing the magnetic flux is used in Electrodynamic or Electrodynamometer type instrument.

If you carefully observe the figure above, you will notice that Fixed Coil as well as Moving coil is in series. Therefore, the direction of current in the moving coil is same as that in the fixed coil. This means that as the direction of magnetic field changes, the direction of current in moving coil also changes. Thus the torque on the moving coil will not change rather it will be unidirectional.

Question.

How is the line from fixed coil to moving coil connected.

They are connected in series.