Slip rings are used in rotating electrical assemblies to make a continuous electrical connection between stationary and moving conductors. This enables the stationary power source to transmit electrical power to the rotating component.

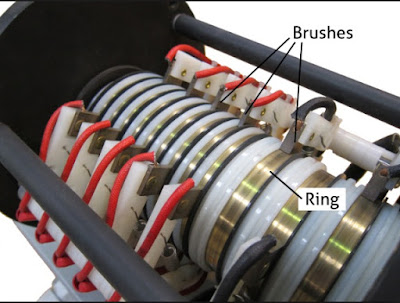

Basically, a slip ring is a band of electrically conductive material mounted on a shaft. Although insulated from the shaft itself, the slip ring is connected to the rotor or rotating assembly through windings or other electrical connections. The outer part of the slip ring is in continuous sliding contact with stationary brushes or other stationary conductors. Figure below shows the arrangement of Rings and Carbon Brushes.

Slip rings are used as a means of providing DC excitation to the rotor of the Alternator. In some excitation schemes the need of a slip ring arrangement may however be eliminated as with the Brushless Excitation System.

The DC supply that we generate after rectification of the alternator output (Static Excitation system is considered here) is stationary but the rotor, to which it is to be fed, is rotating. So we bring out the rotor terminals and at their ends we connect slip rings which rotate along with the shaft. A brush, to which the DC supply is fed, remains in contact with the rotating slip rings and continuously feeds DC into the rotor winding as the slip rings ride over the brushes. We may consider slip ring and brush arrangement as an interface between the rotating rotor and the stationary DC supply.

Nowadays we make use of Brushless Excitation System. In Brushless Excitation System Exciter Alternators to provide DC excitation wherein the field is stationary and the armature is rotating and coupled to the main shaft. The emf induced in the rotating armature of the Exciter Alternator is rectified and fed to the main rotor windings. All this assembly is mounted on the rotor so even the DC supply is rotating and hence we do not require a slip ring arrangement. For detail visit BrushlessExcitation System.

Thank you!