As discussed in the previous post “Speed Control of DC Motor”, speed of DC Motor can be controlled by varying the terminal voltage Vt of the DC Motor. Ward-Leonard Method is the application of this principle where the terminal voltage Vtof DC Motor is varied to control the speed of DC Motor.

Ward-Leonard Method of Speed Control of DC Motor:

The connection diagram of Ward-Leonard Method of Speed Control of DC Motor is shown below.

Ward-Leonard Method of Speed Control of DC Motor uses a Motor Generator set. As shown in the figure above, M is separately excited DC Motor whose speed is to be controlled and G is separately excited DC Generator driven by a three phase AC driving Motor. This combination of AC Driving Motor and DC Generator is called Motor-Generator Set and it converts AC into DC which is fed to DC Motor M.

For starting DC Motor M, its field circuit is first energized and then Generator output voltage is adjusted to a low value by adjusting the field current to a low value of DC Generator as Ea = KaØWm. This is done in order to limit the starting current of DC Motor M. It should be noted that here in Ward-Leonard Method, no starting resistor is added to limit the starting current of DC Motor M and therefore considerable amount of energy is saved during starting of DC Motor M.

As voltage generated by DC Generator = Voltage applied to the DC Motor M

Ea = KaØωm

where ωm = speed of DC Generator G = AC Diving Motor

Therefore by controlling the field current of DC Generator, applied voltage Vt to the DC Motor M is varied and hence speed control of DC Motor M is achieved.

The best feature of Ward-Leonard Method is that we can obtain speed below and above the base / rated speed of DC Motor M. For speed above base speed, the filed current of DC Motor M is varied and for speed below base speed, terminal voltage Vt of DC Motor is changed by varying the field current of DC Generator.

For better utility of DC Motor M, its current Ia is maintained at its rated current during its speed control. Therefore for our discussion we will assume Ia of DC Motor M constant.

When Vt of DC Motor is changed, speed control from lowest possible speed to rated speed of DC Motor is achieved.

As Ia = Constant and Field Flux ØM of DC Motor = Constant

Therefore, Te = KaØMIa= Constant

So, torque remains constant and speed increases from lowest possible speed to rated speed, so Power = (Te×Speed) will increase.

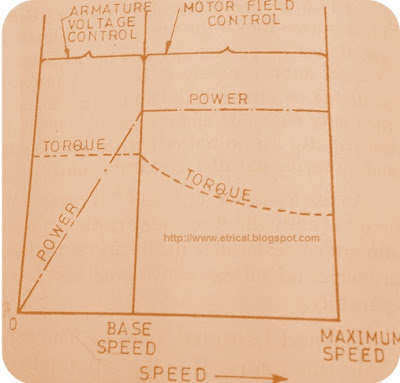

Thus, constant Torque and variable power drive is obtained up to base / rated speed by changing the Armature Terminal Voltage Vt of DC Motor M (Armature Terminal Voltage of DC Motor is changed by varying the field current of DC Generator).

The speed range with armature voltage control = 10/1, the lowest speed is limited by the residual magnetic flux of DC Generator.

As discussed in previous post “Speed Control of DC Motor by Varying Field Flux”, for obtaining speed above base / rated speed of DC Motor M, filed current of DC Motor M is decreased while keeping the DC Generator output voltage Ea constant. As ØM is reduced because of decrease in field current of DC Motor M while Ia is constant hence electromagnetic Torque Te = KaØMIareduces. But power = VtIa remains constant. Thus by this technique, Constant Power Variable Torque Drive is obtained.

The characteristics curve for speed above and below the base / rated speed of DC Motor by Ward-Leonard Method is shown in figure below.

The speed range with field flux control of DC Motor = 3/1 to 4/1, the highest speed in this case is being limited by the armature heating and unstable operation.

How to Brake the DC Motor???

For understanding Braking of DC Motor,

Let the terminal voltage of DC Motor M = Vt and DC Generator output voltage =Ea

If Ea < Vt then DC Motor M will momentarily work like a Generator, DC Generator G as Motor and AC driving Motor as Generator. Therefore kinetic energy of DC Motor M and its load is returned to the supply mains and Braking action on DC Motor take place.

Thus for Braking of DC Motor M, filed current of DC Generator is reduced such that its generated voltage Ea becomes less than the back /counter emf of DC Motor.

The disadvantage of Ward-Leonard method of Speed Control of DC Motor is its high initial cost because three machines of rating equal to full load output are required. This method is rarely used these days because of availability of much cheaper electronic controlled rectifiers.

Thank you!

This has helped me a lot in gaining knowledge and writing my term paper!

Thank you!