Definition of Armature Winding

Armature winding in an electrical machine is that winding which carries the load current. In other words, it can also be defined as the winding in which emf is generated due to air gap field flux. It should be noted here that, air gap flux or working flux is produced due to flow of DC current in the field winding.

Generally armature winding is housed on stator slots and field winding on rotor slots for Synchronous machine. In DC machine, armature winding is placed in rotor slots and field winding on stator slots. For detail, you are requested to read Construction of DC Machine.

Armature winding is made of copper and consists of large number of insulated coils. These insulated coils may have one or more turns. These coils may either be connected in series and parallel depending upon the type of winding required.

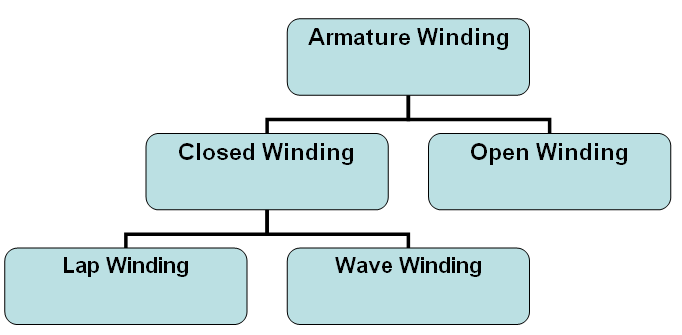

Types of Armature Winding

There are mainly two types of armature winding: Closed Winding and Open Winding

Closed Winding

Closed winding means the winding which is close in itself in the sense that if one starts and traverse the winding then he will return to starting point again. Such type of winding is mainly used for DC machine and AC commutator machine.

Closed armature winding can further be classified into following types: Lap Winding and Wave Winding

Lap Winding

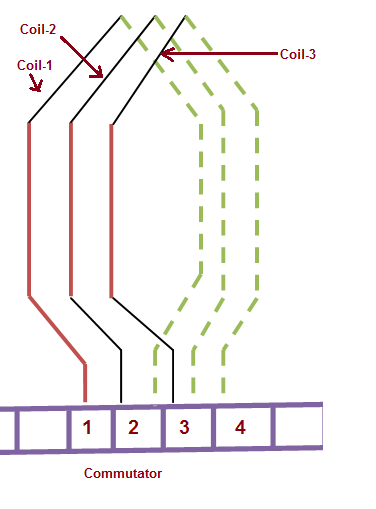

In lap winding the two coil sides of a particular coil are connected to adjacent commutator segment as shown in figure below.

It can be seen from the above figure that, the coil sides of coil-1 are connected to commutator segment 1 & 2 respectively. Thus the commutator pitch for lap winding is 1. Note that commutator pitch is the distance between the two commutator segments to which the two end of coil is joined.

There are three different types of Lap Winding:

- Simplex Lap Winding – The distance between the segments of commutator to which the coil ends are connected is 1. Thus commutator pitch is unity.

- Duplex lap Winding – In duplex lap winding, the commutator pith is 2. This means if one coil end is connected to commutator segment 1 then the other is connected to segment 3.

- Triplex Lap Winding – The commutator pitch for triplex winding is 3. This means if one coil end is connected to commutator segment 1 then the other is connected to segment 4.

Wave Winding

In wave winding, the two coil ends are bent in opposite direction and connected to commutator segments which are approximately two pole pitches apart. Figure below shows a wave winding.

Notice that the both coil ends of coil-1 and coil-2 are bent in opposite direction and connected to commutator segments separated by approximately one pole pitch or 360 electrical degree apart.

There are three types of Wave Winding:

- Simplex Wave Winding

- Duplex Wave Winding

- Triplex Wave Winding

Open Winding

Open winding is one in which the winding terminals are open. Such type of armature winding is used only for AC machine like Induction machine, Synchronous Machine etc. It should be noted here that 3 phase DELTA connected winding in AC machine is a closed circuit, though it can be made open and reconnected in STAR if required. Thus open winding can be open-circuited but closed winding can never be open circuited in any case.

May U Tell Me How The Coil Ends Are Connected On The Commutator Segments In A 3 Pole Armature If The Coils Are Wave Wound

Definitely I can tell but the topic needs to be elaborated which is not possible in comment section. However, I will post on the topic. Please be there.

I really needed this topic Armature Winding and Its Types. You made my day…

Thank you so much

Do you take online classes?